As we step into a new year, the industrial landscape continues to demand more from every machine, every litre of fuel, and every hour on the clock. In this edition, we focus on the theme of strategic resilience. Whether it’s finding the perfect fit for hauling in the African mining sector or choosing a rebuild over a new purchase to bypass global supply chain delays, the goal is the same: maximum productivity with zero compromises on reliability.

We kick off the year with a deep dive into the scientific resurrection of the Cat 789D and explore how the SEM range provides a robust hedge against downtime in mining and agriculture. We also celebrate the incredible community spirit shown at the Sesheng Half Marathon in Kathu, where local athletes proved that neither rain nor rough terrain can stall momentum.

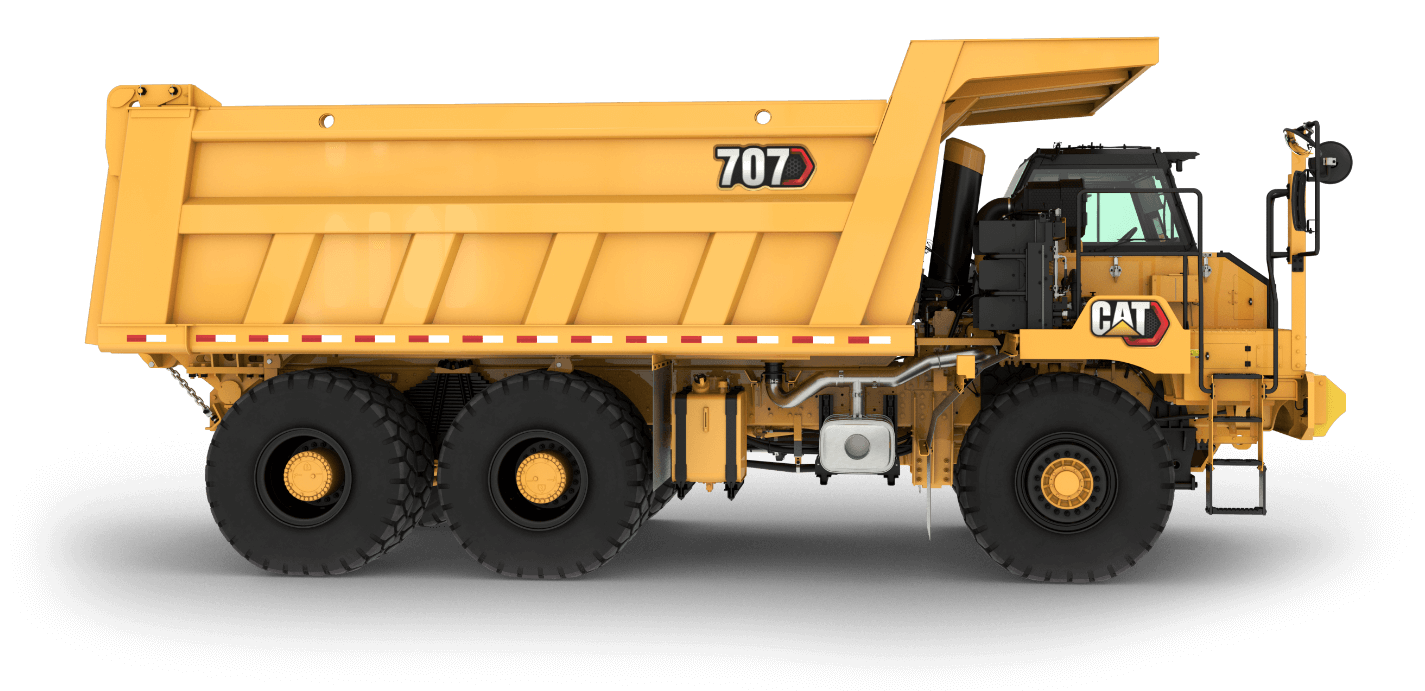

From local events to the continental debut of the CAT 707 Wide Body Truck, we are committed to keeping your operations and our communities moving forward.

Image%20January%2022%2c%202026%20-%204_37PM%20V1%20(1).jpeg)

WHY YOUR NEXT MACHINE PURCHASE MAY BE A REBUILD

We take you inside our technical centre to show the scientific process—from stripping components to bare metal to rigorous dynamometer testing—that ensures as-new performance.

Click below to read the full blog and watch the time-lapse video of a Cat 789D being resurrected by our expert team.

Image%20January%2022%2c%202026%20-%204_37PM%20V1%20(1).jpeg)

WHY YOUR NEXT MACHINE PURCHASE MAY BE A REBUILD

We take you inside our technical centre to show the scientific process—from stripping components to bare metal to rigorous dynamometer testing—that ensures as-new performance.

Click below to read the full blog and watch the time-lapse video of a Cat 789D being resurrected by our expert team.

WHY RELIABILITY IS YOUR BEST HEDGE AGAINST DOWNTIME

Our latest deep dive explores why the SEM range is the strategic choice for ROI-driven professionals who require equipment that is "Built to Last" without the overhead of complex electronics.

From the 50% longer life of the sealed vibe-pod compactors to the high breakout force of the agriculture-leading 636D Wheel Loader, we break down the engineering that prevents a mechanical hurdle from becoming a strategic crisis.

Community Spirit Shines Through the Rain: Sesheng Half Marathon Recap

The day concluded with a formal prize-giving ceremony, marking the end of a rain-soaked but rewarding day of relationship-building and community engagement. From the laughter shared in wet clothing to the pride of seeing local athletes cross the finish line, the event was a true highlight of our regional calendar. We are already looking forward to supporting the community again when the race returns in 2026!

Introducing the CAT 707 Wide Body Truck

A New Standard in Versatile Hauling for the African Mining Sector

The introduction of the CAT 707 Wide Body Truck changes that equation, bringing a purpose-built solution to the African market—launching first in South Africa—that prioritises both immediate productivity and long-term asset value.

This first-of-its-kind offering from Caterpillar represents a strategic shift in the hauling landscape, filling a critical niche between traditional articulated trucks and heavy-duty rigid frames.

EFFICIENCY WITHOUT COMPROMISE

In the wide-body truck segment, the market has historically been dominated by models focusing primarily on low acquisition prices. However, the CAT 707 introduces a full Caterpillar solution designed for high-volume capacity, ensuring that operators do not have to sacrifice engineering integrity for affordability.

The "Wide Body" configuration allows for a significant payload increase, ensuring that the cost-per-tonne remains competitive. By delivering more material per cycle, the 707 addresses the core need for high productivity in environments where operational efficiency is the primary driver of success.

ENGINEERING FOR LONGEVITY: THE REBUILD ADVANTAGE

Perhaps the most significant differentiator for the 707 is its design philosophy. Unlike many machines in this size class that are often treated as short-term assets, the 707 is built to be rebuilt.

- Mid-Life Support: The machine is engineered to undergo a full drivetrain and powertrain rebuild, effectively doubling its working life compared to many competitor models.

- Component Commonality: To reduce downtime and inventory costs, the 707 shares cab features with the 773 series and engine components with the 730 series. This commonality ensures that site mechanics are already familiar with the technology and that parts are readily available within existing supply chains.

In the modern mining environment, safety is non-negotiable. The 707 features a best-in-class ROPS (Roll-Over Protective Structure) and FOPS (Falling Object Protective Structure) integrated cab. By bringing Tier 1 safety standards to the wide-body truck segment, it allows junior miners and contractors to meet the stringent safety requirements of major mining houses without the prohibitive costs of larger-scale machinery.

A FLEXIBLE APPROACH TO FLEET MANAGEMENT

Recognising that capital outlay remains a significant consideration for State-Owned Entities and contract miners, the rollout of the 707 is supported by flexible financing and Customer Value Agreements (CVAs). These service plans are specifically designed to support the mid-life rebuild process, ensuring the machine reaches its maximum return on investment.

Whether managing a short-term infrastructure project or a multi-year mining contract, the 707 offers a scalable, durable alternative that prioritises performance without compromising on the reliability the sector demands.

In the heart of the African landscape, where the earth demands resilience, the 707 stands as a testament to the enduring cycle of strength—built to move the world today, and engineered to rise again for the challenges of tomorrow.

DID YOU KNOW?

CAT engines offer an integrated system.

Latest campaigns

CAT® 707 WIDE BODY TRUCK

.jpg)

CAT® COMPACTORS PERFORMANCE THAT PAYS OFF

.png)

CAT® Medium Wheel loaders

Reliability That Delivers Long-Term Value

As you plan your fleet requirements for the months ahead, remember that our team is here to help you match the right technology to your specific operational needs, backed by a support network that spans the continent. Thank you for your continued partnership and for being part of our journey. We look forward to seeing you on-site and in the field!

Contact us today to get insights That Support Smarter Fleet Decisions

Articulated trucks

Articulated trucks

-1.webp) Dozers

Dozers

-1-1.png) Backhoe Loaders

Backhoe Loaders

Hydraulic Mining Shovels

Hydraulic Mining Shovels

ELECTRIC POWER

ELECTRIC POWER

MARINE POWER

MARINE POWER

INDUSTRIAL

INDUSTRIAL

OIL AND GAS

OIL AND GAS

.png) RENTALS

RENTALS